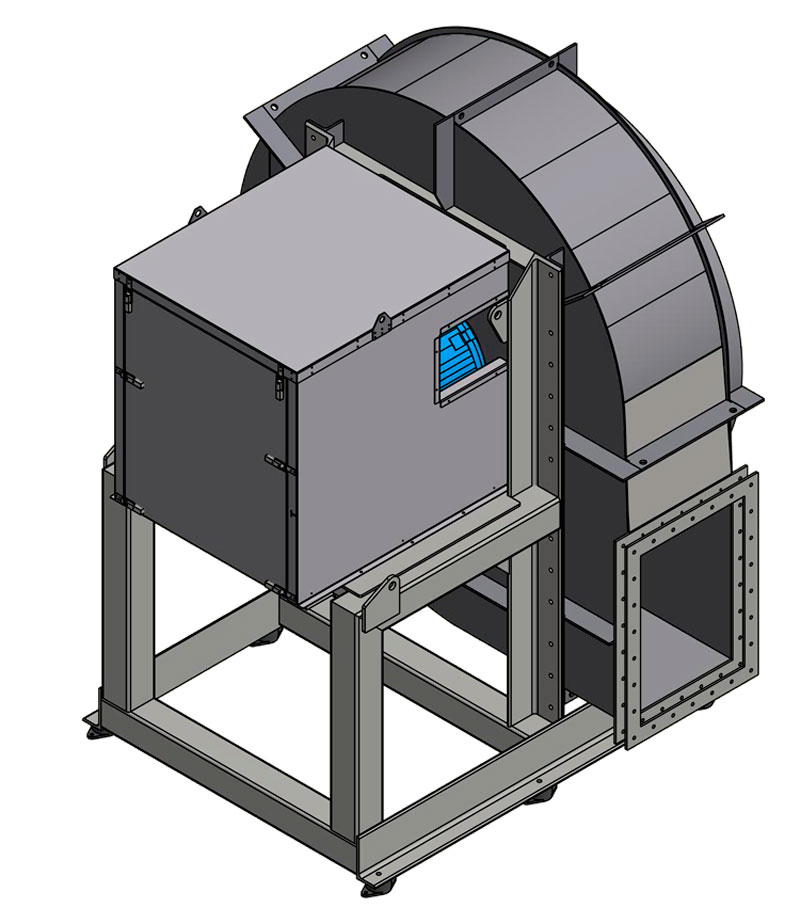

Industrial Fans for Food Processing Applications & pharmaceutical industry

Designing and manufacturing centrifugal fans for food processing applications and the like place special demands on both production processes and the fan design.

With more than 50 years of experience, we know these demands in detail and take pride in supplying the very best fan each time. In particular, we have supplied hundreds of fans for engineering companies that are market leaders in designing production lines for the food industry. Our fans are used e.g., in whey production lines, spray drying processes etc.

This has resulted in a fan design that complies with the stringent hygienic requirements and provide easy access for cleaning. All fans can be equipped with CIP for internal cleaning purpose. At BarkerBille we consult our customers regarding the design and placement of CIP nozzles to ensure the best CIP cleaning results.

Example of food processing & pharmaceutical fans:

- Supply / pressure fans

- Exhaust / suction fans

- CIP Purge fan

- Cooling fans

- Purge Air fans

- Regeneration fans

- Fluidzed Bottom Air Fan

- Filter fans

- Spray drying fans

Special Requirements & Hygienic Fan Design

A hygienic design of the industrial fans used in food processing is paramount to avoid contamination and production loss.

Our fans for food processing plants are constructed to avoid problematic areas, manufactured in stainless or acid-proof steel, surface-treated according to need and welded with maximum care.

- easy-to-clean

- sanitary construction

- highly energy-efficient

- cost-competitive.

To meet the demands for a hygienic design and construction, we offer among others:

- CIP for internal cleaning

- stainless steel construction

- special welding of the external stiffeners for even easier cleaning

- special surface treatments

- special certificates and approvals.