24 Centrifugal Fans for Industrial Applications

24 Centrifugal Fans for Industrial Applications

For larger flexibility to design just the right fan, we have created ten new centrifugal fan types. These new types enable us to offer fans that are even more spot on when it comes to performance requirements and price level.

– With these new fans we’re to fulfill a market demand for more cost-efficient fans and customized 3D drawings instantly. The 3D drawings give customers large flexibility as they can incorporate the exact fan into their system design immediately after receiving a quotation. At the same time, the construction is lighter and thus more cost-efficient, Sales Manager from BarkerBille, Søren Olesen, explains.

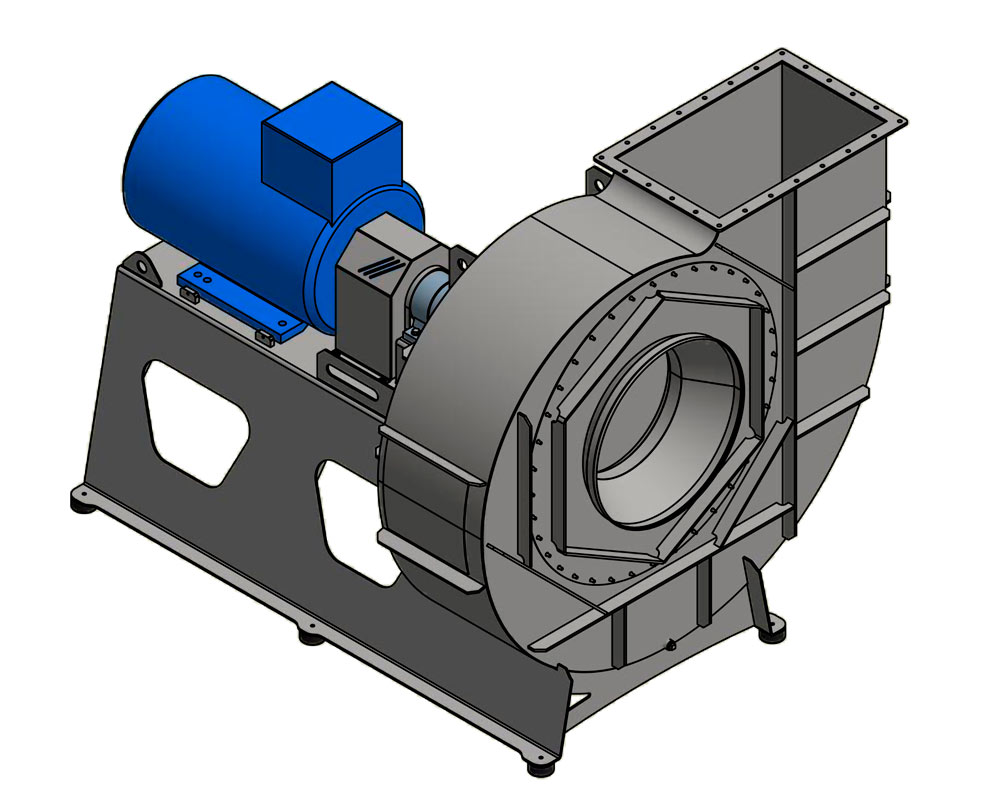

The new fans are redesigns of the former Moldow fans, which are now also manufactured with a steel plate base for a more cost-efficient alternative, when there is no need for a very robust, heavy design or very special construction. Together with the former Bille fans they constitute the new line of fans called Industrial Line.

Two New Industrial Fan Design Lines

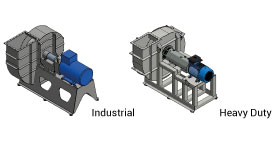

At the same time, to streamline our centrifugal fan product range, we have divided our fans into two new design lines: Industrial Line and Heavy Duty Line.

The Industrial line fans are customized and low energy-consuming fans with steel plate. The Industrial line fans are fully-integrated into BarkerBille’s 3D software, which means that customers can get an exact 3D drawing together with their quotation.

The Heavy Duty line fans are with steel profiles base and can to a greater extent be custom-made to suit very special customer requirements. This can for example be requirements for a special type of construction material, belt-drive, emergency motor or special placement of the motor. They are particularly suitable for environments with heavy loads, vibrations or corrosive areas.

– With the new Industrial Line fans, we have expanded our range of cost-efficient, lighter constructed fans. However, there’s still a high demand for fans with a more robust construction, which our Heavy Duty Line fans have. In those cases, our skilled construction team and flexible own production is a huge advantage as they allow us to design fans exactly according to our customers’ requirements, Søren Olesen explains.

24 Different Fan Types

The two lines comprise 24 different fans in total, and this comes with many advantages.

– It’s crucial to have different types as they all have their distinctive features and differ in the material that they can transport, Søren Olesen says.

The names of the Industrial Line fans are based on the original types, and include impeller size for easy comparison. The line now includes 14 types.

The Heavy Duty Line includes 10 fans, and names and construction equal the original Moldow fans.