Pyrolysis Fans for High Temperatures

For fans for pyrolysis, knowing how to maintain the required high operating temperature and ensure a heat resistant construction is crucial. BarkerBille has supplied several fans for use in pyrolysis processes and work closely with our customer to make sure that the exact requirements are met.

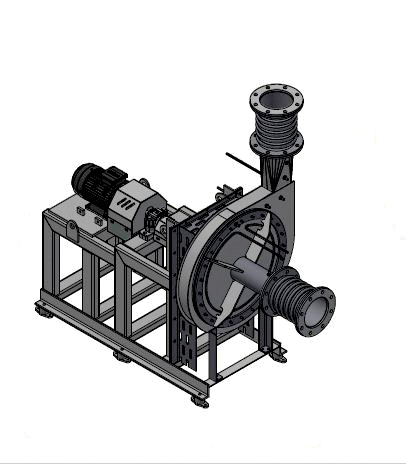

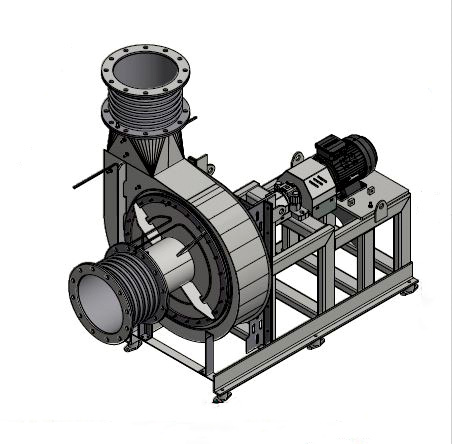

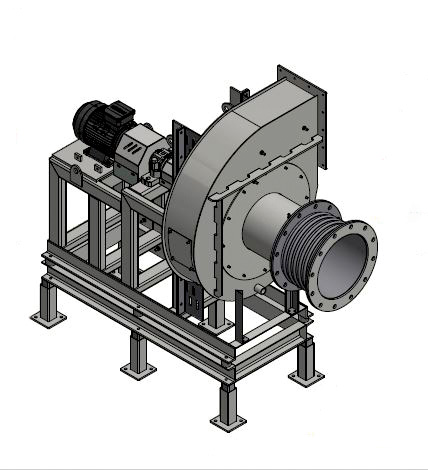

Customized Pyrolysis Centrifugal Fans

Among others, BarkerBille has supplied these three fans for Stiesdal A/S’ SkyClean pyrolysis test plant in Skive, Denmark. The three fans are an air circulation fan for a heat exchanger, a gas recirculation fan and a gas extraction fan to extract/recirculate pyrolysis reactor gases.

The fans are designed to have a start-up temperature of 450oC and a continuous operation temperature of 550oC. This is achieved by special heating and insulation of the housing as it is paramount to the pyrolysis process that this temperature is ensured.

The media temperature when operating with pyrolysis gases can reach up to 600oC when passing through the fan. Therefore, to withstand the high temperature and ensure a strong construction, the fans are made in stainless steel and with insulated fan housing.

ATEX-approved, Gas Tight Fans for Pyrolysis

Due to the application, the fans are designed according to ATEX category 2G (zone 1) inside and made with a gas tight construction.

Gas tight fans always go through a leak test at our workshop besides the usual FAT before dispatch.

Looking for a Pyrolysis Centrifugal Fans manufacturer?

If you are looking for fans for pyrolysis, we would be delighted to have a look at your project and offer the best fan for the application.

Fill out the contact form below to get in touch.

Contact Us for More Information

At BarkerBille, we are more than happy to assist you from start to finish.

Feel free to contact us, and we will be happy to answer any questions you may have. This way, we can guarantee a fan designed uniquely for your specific needs.